Toilet system protected through sewage water tank

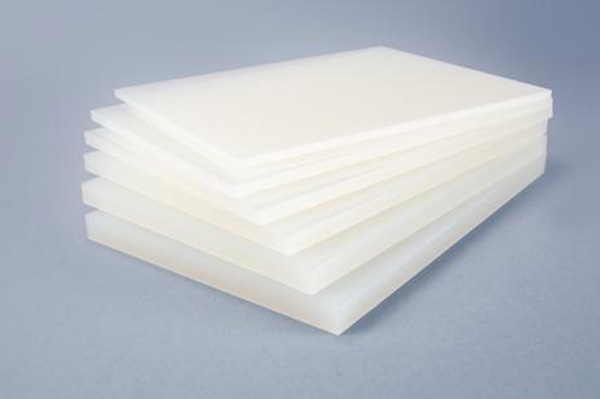

For a well-known German manufacturer AGRU supplies thin-walled PE-sheets with one-sided polyester fabric backing which are fabricated to a special inliner by thermoforming and welding. The fabricated thermoplastic lining is covered with a carbon fibre coating to withstand the operating pressures and loads in actual operation conditions.

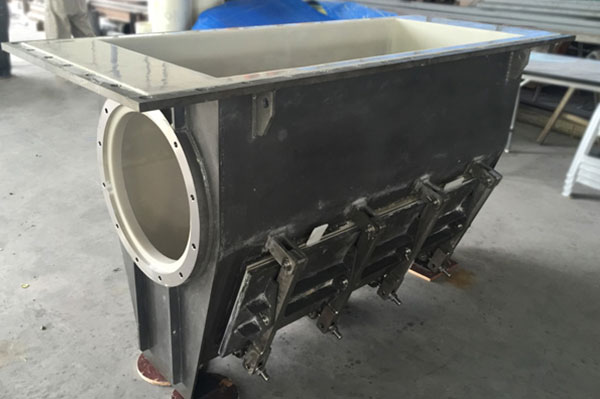

The tank made out of sheets

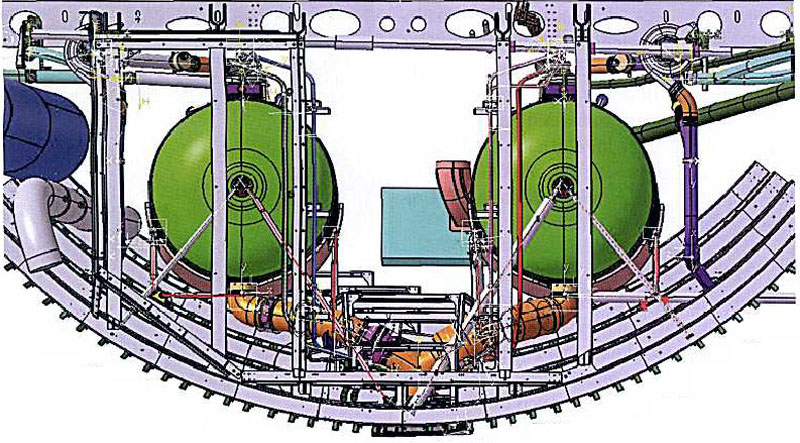

The construction plan

This is how a sewage water tank is created for the vacuum toilet system of the Airbus A340-500/600 HGW. It is a special weight optimized type – every kilogram is important. The standard system of two smaller tanks with stainless steel inliners has been replaced by one single large tank to optimize weight and performance.

Each of the tanks on boards has a volume of 720 litres, whereby 570 litres are used for the storage of sewage water coming from the onboard toilets.

Beside the storage of the sewage water from toilets, the inside surface of these tanks is loaded with chemical cleaning agents and objects which hit the surface with high energy.

The leak tightness and chemical resistance is reached by the special PE liner. The weight of a completed tank element with all attached parts is approximately 50 kg. A completely filled tank can withstand a load of 9 g. A test with an acceleration of 20 g is applied for a short time, which simulates a load of 12.5 tons on the supports. A life time of 30 years is guaranteed.