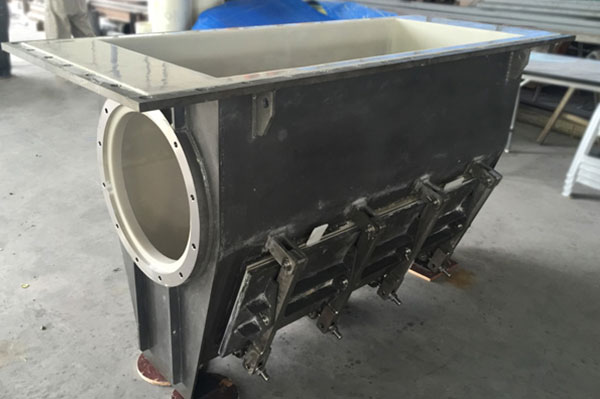

PVDF-el ESD Fabric Backed Sheets inside a waste-water tank

The company Kunststoffe Lauing Nachf. GmbH was tasked by a prestigious chemical group with the lining of a steel tank for waste water containing cresol and toluene. Since the tank was installed in an explosion-prone area, the highly innovative polymer PVDF-el ESD was called into action.

Date: 2020

Fabricator: Kunststoffe Lauing Nachf. GmbH

Distributor: Frank GmbH

Location: Germany

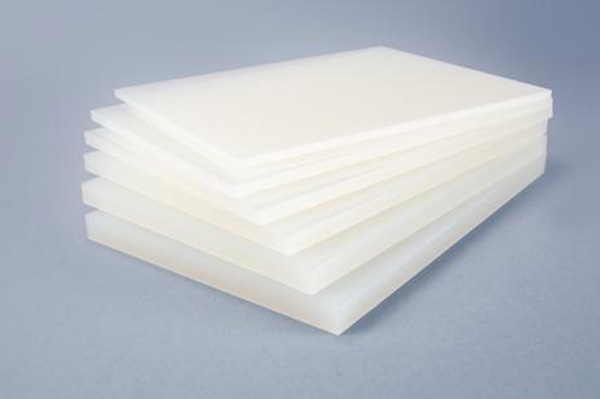

Material: PVDF-el ESD SK+ Fabric Backed

Medium: Waste water containing cresol and toluene

Dimension: Ø 2400 mm x 3600 mm

Temperature: -10 °C up to +90 °C

Conventional plastics are not electrically conductive and are therefore not suitable for applications in an EX-Zone according to the European ATEX Standard 2014 / 34 / EU since through electrostatic charging of the material a spark could strike and possibly initiate an explosive reaction.

To utilize the benefits of the polymer PVDF in regards to its excellent thermal and chemical resistance in this application area, a special compound PVDF-el ESD (Polyvinylidenfluorid ElectroStaticDischarge) was processed. Through the addition of carbon black and by grounding of products from this compound the ability of electrostatic charging can be averted. According to EN 13463-1 it is assumed that with a surface resistance ≤109 Ohm the electrical conductivity is high enough to avoid any electrostatic charging. Electrically conductive products from AGRU typically show a surface resistance which is even smaller by three powers of ten (≤106 Ohm) and can therefore be installed in EX-Zones.

The electric conductivity provides a great and necessary benefit for the application but it also comes with challenges. The conventional spark testing, which is normally used to ensure the leak-tightness of lined tanks is no longer possible since the material is now conductive. It is therefore inevitable for competent fabricators like Kunststoffe Lauing Nachf. GmbH to ensure the leak-tightness of such projects through the highest welding quality and innovative testing methods.