In the course of the construction of a new copper mining plant at a Bulgarian chemical company, a 140-meter-high flue gas stack for exhaust air containing sulfur was lined with laminated ECTFE sheets from AGRU.

| Project date | 2020/2021 |

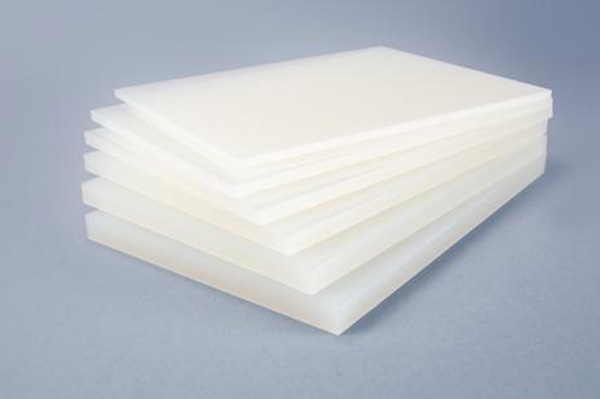

| Products | ECTFE SK+ 3mm |

| ECTFE Tubes ∅ 90 x 2.8 mm | |

| ECTFE Welding rod ∅ 3 mm | |

| Country | Bulgaria |

| Temperature | max. 75°C |

| Media | Exhaust gases |

| Distributor | Auro / Auro Bulgaria |

| Processor | Rimisar Ltd. |

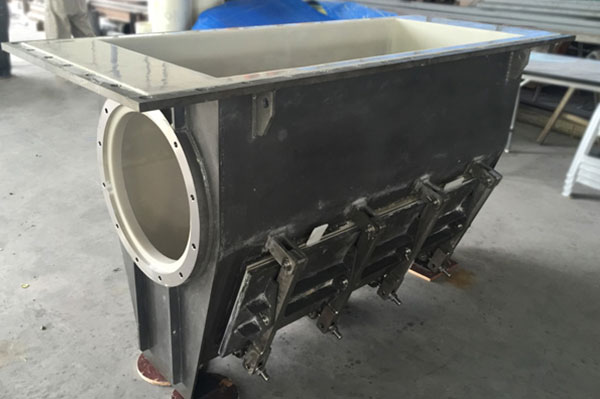

The aim of the project was to install an ECTFE SK+ dual-laminate stack for a new power plant in Bulgaria. The processor of the project is Rimisar, which was supplied by the company Auro / Auro-Bulgaria as a distributor. By processing copper ores, a chemical company produces sulphurous waste gases, which are burned in a power plant to generate energy. Sulphuric acid is extracted from the sulphurous waste gases and the purified waste gas air is then released into the environment via the flue gas stack. In this way, a waste product is turned into energy and a saleable industrial product that can be used in a wide range of applications. Sulphuric acid is widely used in the petrochemical and metallurgical industries, but especially in the fertilizer industry. Due to the properties of this sulphuric exhaust, which would attack a variety of other plastics as well as metals, it was decided to use a dual laminate solution. This solution consists of the fluoroplastic ECTFE as lining material and glass fibre reinforced plastic (GRP).

The GFRP structure provides the static and mechanical strength required to support a flue gas system of this dimension. The ECTFE is responsible for the chemical resistance of this composite and protects the GFRP. The application temperature of the flue gas stack is 66 – 70 °C. In exceptional cases, the maximum temperature can be 75 °C. The challenge in the realization of this project was the production of the films to the desired length specified by the customer. The roll length of 10.06 meters to line the 3.2-meter diameter chimney in one piece proved to be ideal for the customer. The big advantage was to avoid material waste and additional welding.