Pipeline with integrated leak detection

Our local partners GPA Flowsystems AB and GT Plast Montage AB provided a perfect solution, making use of PVDF/PVDF double containment piping systems from AGRU. Therefore, a pipeline with leak detection and integrated heating system was required.

Requirements

Outokumpu Stainless AB is a global leader in the stainless steel industry with the vision to be the undisputed number one. For environmental reasons and also to reduce the costs of pickling acids, a new acid regeneration plant was built. Thus, a pipeline to transport a mixture of hydrofluoric (HF) and nitric acid (HNO3) from the pickling line to the acid regeneration unit was installed.

Because of a recommendation of a research project by Swerea KIMAB Outokumpu decided to use PVDF material for pipes. A double containment piping with a leak detection system was additionally required under the following conditions:

- Design temperature: 70 C

- Design pressure: 6 bar

- HNO3 <250 g/l

- HF <80 g/l

- Metal content (dissolved) <35 g/l

Most parts of the piping system were installed outdoors on pipe brackets at a height of up to 12 m. The exposure to UV radiation and the outside temperature ranging from -30 °C up to +50 °C had to be considered. In order to prevent the mixed acids from freezing, i.e. crystallisation, the temperature must be kept above +7 °C at all times, preferably around +40 °C. This is especially challenging if the pipeline is not operated during winter months.

Solution

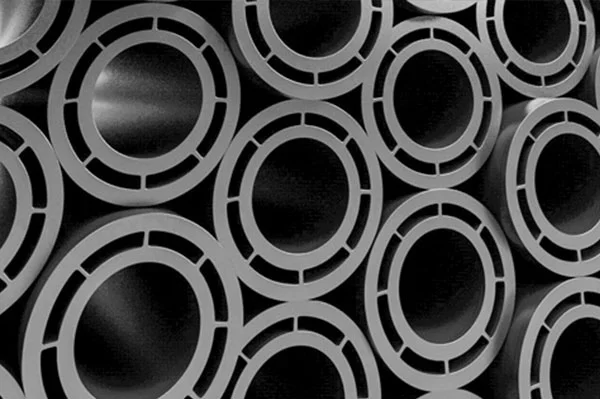

Based on the support of AGRU, the Swedish companies GPA Flowsystems AB and GT Plast Montage AB developed a solution based on a PVDF/PVDF double containment piping system. The inside pipe with an OD 63 mm SDR 21 according to ISO 10931 is capable of withstanding the above mentioned operating conditions. The outside pipe with an OD 110 mm SDR 33 provides extra safety in case of leakage of the inner pipe. As the outer pipe is made from PVDF, it is fully resistant to the pickling acid.

The space between the two pipes was used to install a leakage detection system. Therefore, the 600 m long pipeline was divided into 16 sections, each equipped with a leakage control sensor. In order to avoid a drop in media temperature below +7 °C, a heat tracing cable was used. It was installed on the outside surface of the OD 110 mm pipe. Finally, the whole system was covered with an insulation layer.

Moreover, an important issue of this project was to construct the entire piping system as a fixed system, i.e. to inhibit a thermal expansion of the inner as well as the outer pipe. This could be achieved by using anchors whenever the piping system changes direction and as a result cost-intensive expansion loops on the pipe bridges were avoided.

Installation

For the joining of the PVDF/PVDF double containment piping system simultaneous welding based on non-contact infrared welding was chosen. The welding parameters were developed especially for this project in order to ensure a high integrity of the welds and a long-lasting quality. To guarantee a smooth installation start, a welding training was conducted by an experienced project supervisor from AGRU at the beginning of the project.

It took about 10 weeks to finish the installation. The parameters of each weld were automatically recorded by the SP infrared welding machine. Additionally, each weld was marked with a label immediately after it was finished. At the end of the project a third party inspection confirmed the high quality of the joints.

Double containment pipes double the safety

Double containment piping systems from AGRU have been used successfully in a wide range of industrial applications for many years. The inner pipe transports the media. The outer pipe provides extra safety if leakage of the inner pipe occurs. The material is selected in order to ensure full chemical resistance.

For leak detection different methods are available. The sensors are installed in the space between inner and outer pipe. The outer pipe in combination with a leak detection system provides protection to workers and buildings and helps to prevent secondary damage such as pollution and ground water contamination.