The tap water in Petronell-Carnuntum, the town where the Romans once settled, comes from deep wells in the Danube floodplains and is rich in calcium and magnesium. However, too much calcium in the water also brings numerous disadvantages: dirty glasses, defective appliances, higher consumption of detergent and dry skin when showering. AGRU supplied numerous components made of PP for a desalination plant that feeds soft water into the pipelines.

In order to maintain the security of supply with drinking water of spring water quality, EVN Wasser will invest around 25 million euros over the next 4 years. The natural filter plant in Petronell-Carnuntum will be the fifth of its kind. It is expected to supply 50,000 inhabitants with soft water every day. “Water hardness is an essential quality characteristic. By using very fine membranes, the hardness level is reduced to 10-12°dH purely mechanically,” explains EVN Board Spokesman Stefan Szyszkowitz.

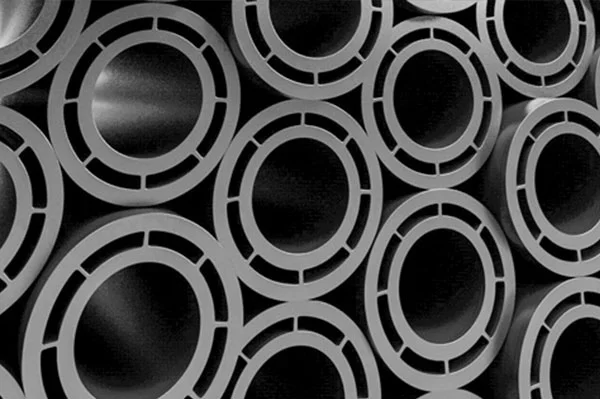

In reverse osmosis, as the water desalination process is called, the material PP plays a major role. The permanent freedom from corrosion and resistance of this engineering plastic to salts and minerals, as well as the smooth inner surfaces of PP piping, ensure decades of maintenance-free operation. Since high operating pressures also prevail in such plants, PP with its high creep strength is the first choice. The treatment plant was installed by GWT Wasser und Wärmetechnik. AGRU supplied 200 linear meters of AGRUCHEM PP pipes and fittings from 50 mm to 400 mm.

Natural filtration in detail

For the new natural filter plant, a hall with a size of approx. 60 m x 30 m and a height of up to 11 m had to be built. Inside there is highly complex technology. The well water passes through 4 x ultrafiltration, 4 x reverse osmosis, 6 x activated carbon filtration and 4 x UV disinfection. This not only effectively removes hardness constituents, but also significantly reduces other undesirable ingredients, such as nitrate. Leyrer & Graf used 700 linear meters of AGRULINE pipes and fittings up to 560 mm for underground pipelines. Container builder Bilek & Schüll supplied numerous containers and tanks made of AGRU PP sheets. Here, the material PP scores with its higher strength and rigidity. The plant has been in operation since the beginning of this year. When completed, it will produce 300 l/s of soft drinking water.